1. Kuomesa naironi PA66

Vacuum drying:tembiricha ℃ 95-105 nguva 6-8 maawa

Kuomesa mhepo inopisa:tembiricha ℃ 90-100 nguva anenge 4 maawa.

Crystallinity:Kunze kwenaironi inoonekera, naironi zhinji icrystalline mapolima ane high crystallinity. Iko kusimba kwesimba, kupfeka kuramba, kuoma, lubricity uye zvimwe zvimiro zvezvigadzirwa zvinovandudzwa, uye iyo yekuwedzera yekuwedzera kwemafuta coefficient uye kunyudzwa kwemvura kunowanzo kuderera, asi hazvikonzerese kujeka uye kukanganisa kuramba. Mold tembiricha ine simba guru pacrystallization. Iyo yakakwirira tembiricha ye mold, inokwira iyo crystallinity. Iyo yakaderera tembiricha yekuumbwa, inodzika iyo crystallinity.

Shrinkage:Zvakafanana nemamwe mapurasitiki ekristalline, nylon resin ine dambudziko guru rekuderera. Kazhinji, shrinkage yenylon inonyanya kuenderana nekristalllization. Kana chigadzirwa chacho chine yakakwirira yekristallinity, shrinkage yechigadzirwa ichawedzerawo. Kudzikisa tembiricha yekuumbwa, kuwedzera kudzvanywa kwejekiseni, uye kudzikisa tembiricha yechinhu panguva yekuumbwa kunoderedza kuderera, asi kushushikana kwemukati kwechigadzirwa kuchawedzera uye zvichave nyore kukanganisa. PA66 shrinkage ndeye 1.5-2%

Midziyo yekuumba: Paunenge uchigadzira naironi, teerera kudzivirira "kukanda chiitiko chemhino", saka mapfumo ekuzvivharira ega anowanzo shandiswa kugadzirisa zvinhu zvenaironi.

2. Zvigadzirwa uye molds

- 1. Ukobvu hwemadziro echigadzirwa Chiyero chekuyerera kwenylon chiri pakati pe150-200. Ukobvu hwemadziro ezvigadzirwa zvenaironi hausi pasi pe0.8mm uye kazhinji inosarudzwa pakati pe1-3.2mm. Mukuwedzera, iyo shrinkage yechigadzirwa inoenderana nemadziro emadziro echigadzirwa. Kuwanda kwemadziro emadziro, ndiko kukura kuderera.

- 2. Exhaust Kufashukira kukosha kwenylon resin kunosvika 0.03mm, saka exhaust hole groove inofanirwa kudzorwa pazasi 0.025.

- 3. Tembiricha yeMold: Zviumbwa zvine madziro matete akaoma kuumba kana kuti zvinoda kupenya kwekristaro zvakanyanya zvinodziiswa uye zvinodzorwa. Mvura inotonhora inowanzo shandiswa kudzora tembiricha kana chigadzirwa chichida kumwe kusanduka.

3. Nylon molding process

Kupisa kwebhare

Nekuti nylon icrystalline polymer, ine yakakosha kunyungudika. Iyo tembiricha yedhiramu yakasarudzwa yenylon resin panguva yekuumbwa kwejekiseni ine chekuita nekuita kweresin pachayo, zvishandiso, uye chimiro chechigadzirwa. Nylon 66 inosvika 260°C. Nekuda kwekusagadzikana kwekudziya kwenylon, haina kukodzera kugara mubhodhoro pakushisa kwepamusoro kwenguva yakareba kudzivirira kushanduka uye kutsvuka kwechinhu. Panguva imwecheteyo, nekuda kwemvura yakanaka yenylon, inoyerera nekukurumidza mushure mekunge tembiricha yadarika kunyungudika kwayo.

Jekiseni pressure

Iyo viscosity yenylon melt yakaderera uye fluidity yakanaka, asi iyo condensation kumhanya inokurumidza. Zviri nyore kuve nematambudziko asina kukwana pane zvigadzirwa zvine maumbirwo akaomarara uye madziro akatetepa, saka yakakwira jekiseni pressure ichiri kudiwa.

Kazhinji, kana kudzvinyirirwa kwakanyanya, chigadzirwa chichava nezvinetso zvekufashukira; kana kudzvinyirirwa kwakanyanya kuderera, chigadzirwa chichava nekuremara senge ripples, bubbles, pachena sintering marks kana zvigadzirwa zvisina kukwana. Kudzvanywa kwejekiseni kwemarudzi mazhinji enylon hakupfuuri 120MPA. Kazhinji, inosarudzwa mukati meiyo 60-100MPA kuti isangane nezvinodiwa zvezvizhinji zvigadzirwa. Chero bedzi chigadzirwa chisina kukanganisa senge mabubbles uye dents, kazhinji hazvifadzi kushandisa yakakwira kubata kumanikidza kudzivirira kuwedzera kushushikana kwemukati kwechigadzirwa. Kumhanyisa jekiseni Yenylon, kumhanya kwejekiseni kunokurumidza, izvo zvinogona kudzivirira ripples uye kusakwana kwekuzadza mold kunokonzerwa nekumhanya kwakanyanya kutonhora. Iyo yekumhanyisa jekiseni kumhanya haina kukosha kwakakosha pakuita kwechigadzirwa.

Mold tembiricha

Mold tembiricha ine imwe pesvedzero pane crystallinity uye molding shrinkage. High mold tembiricha ine yakakwira crystallinity, yakawedzera kupfeka kuramba, kuoma, elastic modulus, kuderera kunyura kwemvura, uye kuwedzera kuumbwa kwechigadzirwa; low mold tembiricha ine yakaderera crystallinity, yakanaka kuoma, uye yakakwirira elongation.

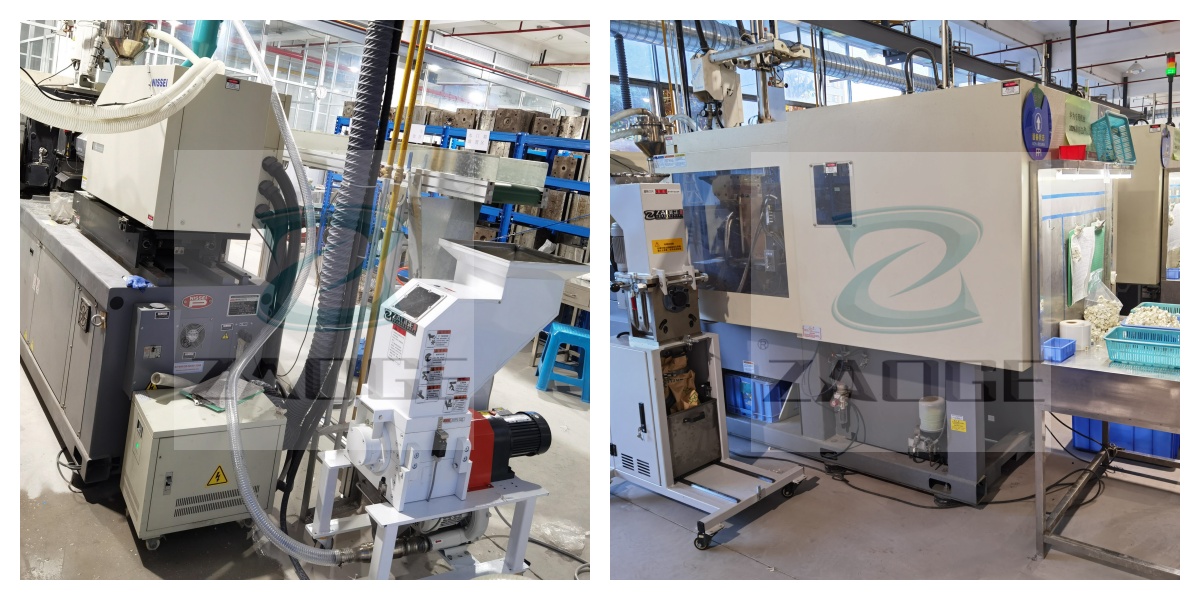

Majekiseni ekuumba maworkshops anoburitsa sprues uye anomhanya zuva rega rega, saka isu tingaite sei zviri nyore uye zvinobudirira kudzoreredza masprues nemamhanyi anogadzirwa nemichina yekuumba jekiseni?

ZvisiyeZAOGE kuchengetedzwa kwezvakatipoteredza uye inochengetedza zvinhu inotsigira mudziyo (plastiki crusher)zvemichina yekuumba jekiseni.

Iyo chaiyo-nguva inopisa yakakuya uye yakadzokororwa sisitimu iyo yakanyatso kugadzirirwa kupwanya yakakwirira-tembiricha yakaraswa sprues uye vanomhanya.

Yakachena uye yakaoma yakapwanyika zvimedu zvinongodzoserwa kumutsetse wekugadzira kuti ugadzire nekukurumidza Injection yakaumbwa zvikamu zvigadzirwa.

Zvimedu zvakachena uye zvakaoma zvakapwanyika zvinoshandurwa kuita zvemhando yepamusoro zvekushandisa panzvimbo yekudzikisa.

Inochengetedza zvigadzirwa nemari uye inobvumira kudzora mutengo uri nani.

screenless inononoka kumhanya ganulator

Nguva yekutumira: Jul-24-2024