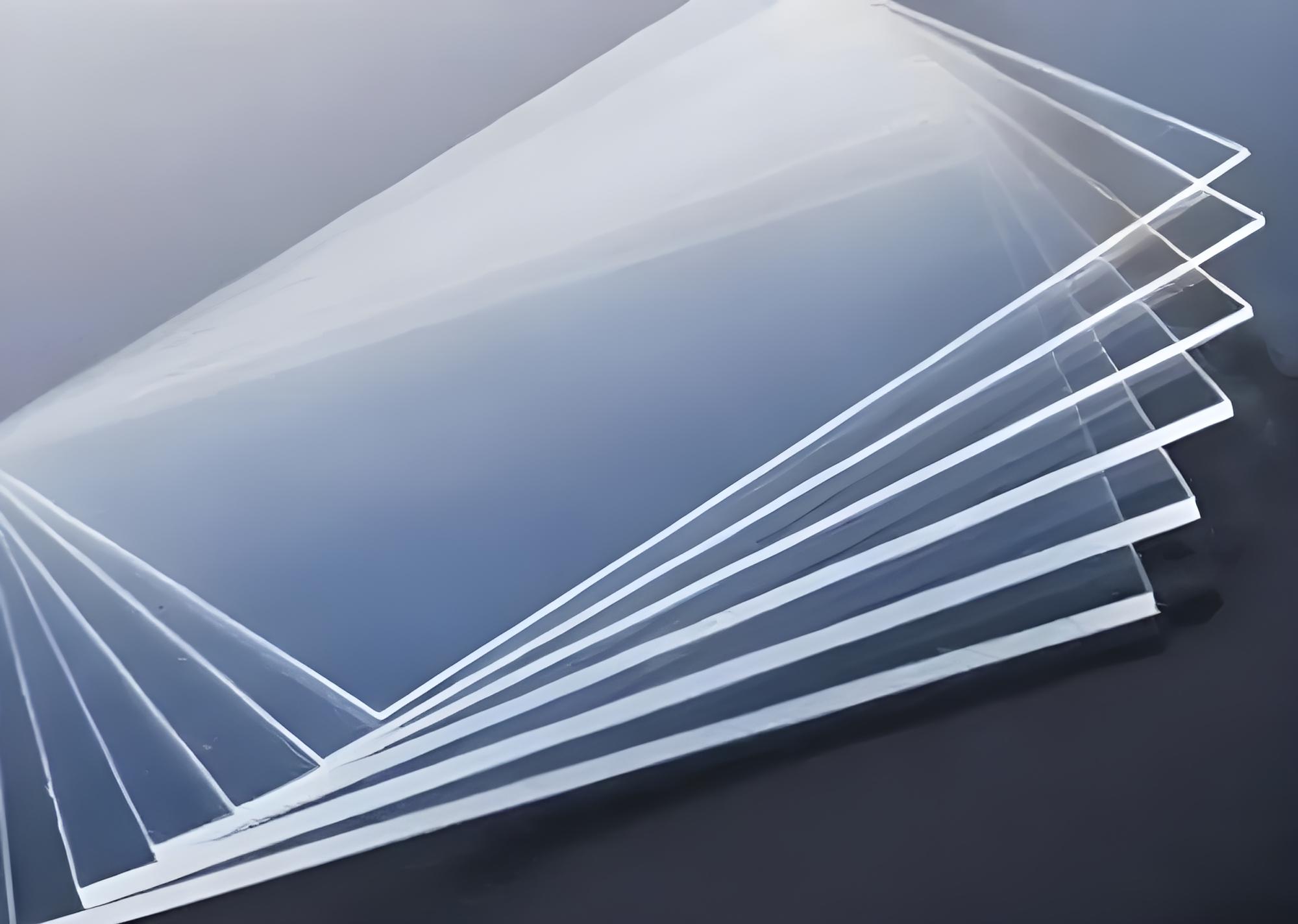

Zita remakemikari re acrylic ndiro polymethylmethacrylate (PMMA muChirungu). Nekuda kwekukanganisa kwePMMA senge kuomarara kwepasi pasi, kukwesha nyore, kushomeka kwekushomeka, uye kutadza kuumbwa kwekuyerera kwekuita, kugadziridzwa kwePMMA kwakaonekwa imwe mushure meimwe. Zvakadai secopolymerization yemethyl methacrylate ine styrene uye butadiene, kusanganiswa kwePMMA nePC, nezvimwe.

Kuyerera maitiro ePMMAyakaipisisa kupfuura iyo yePS uye ABS, uye iyo yakanyunguduka viscosity inonyanya kunetseka nekushanduka kwekushisa. Munguva yekuumbwa, iyo melt viscosity inonyanya kuchinjwa zvichienderana nekupisa kwejekiseni. PMMA iamorphous polima ine tembiricha yekunyungudika inodarika 160°C uye tembiricha yekuparara ye270°C.

1. Kuraswa kwepurasitiki

PMMA ine imwe dhigirii yekunyura kwemvura, ine mwero wekutora mvura we 0.3-0.4%. Kuumba jekiseni kunoda hunyoro huri pasi pe0.1%, kazhinji 0.04%. Kuvapo kwehunyoro kunokonzera mabhubhu, mitsetse yemhepo, uye kuderedzwa kujeka mukunyunguduka. Saka inoda kuomeswa. Iyo yekuomesa tembiricha ndeye 80-90℃uye nguva yekuomesa inopfuura maawa matatu. Zvinhu zvakadzokororwa zvinogona kushandiswa 100% mune dzimwe nguva. Iyo chaiyo mari inoenderana nemhando yezvinodiwa, kazhinji inodarika 30%. Zvinhu zvakadzokororwa zvinofanirwa kudzivirirwa kubva pakusvibiswa, zvikasadaro zvinokanganisa kujeka uye zvimiro zvechigadzirwa chakapedzwa.

2. Kusarudzwa kwejekiseni molding machine

PMMA haina zvakakosha zvinodiwa zvemajekiseni ekuumba michina. Nekuda kwehupamhi hwekunyungudika kwayo, inoda gomba rakadzika uye gomba rakakura remuromo. Kana izvo zvinodikanwa zvesimba zvechigadzirwa zvakakwirira, sikururu ine yakakura chikamu ratio inofanirwa kushandiswa kune yakaderera-tembiricha plasticization. Mukuwedzera, PMMA inofanira kuchengetwa muhopi yakaoma.

3. Mold uye gedhi kugadzira

Kupisa kwe mold kunogona kusvika 60℃-80℃. Iyo dhayamita yemugero mukuru inofanirwa kuenderana nemukati taper. Iyo yakakwana kona ndeye 5° ku7°. Kana uchida kubaya jekiseni mold 4mm kana pamusoro zvigadzirwa, kona inofanira kuva 7° uye dhayamita yechiteshi chikuru chinofanira kunge chiri 8 kusvika 8°. 10mm, kureba kwegedhi hakufanire kudarika 50mm. Kune zvigadzirwa zvine madziro ukobvu asingasviki 4mm, iyo inoyerera dhayamita dhayamita inofanira kuva 6-8mm

Kune zvigadzirwa zvine madziro emadziro makuru kupfuura 4mm, iyo dhayamita yemumhanyi inofanira kuva 8-12mm. Kudzika kweiyo diagonal, feni-yakaita uye yakatwasuka siketi masuwo anofanirwa kunge ari 0.7 kusvika 0.9t (t ndiko ukobvu hwemadziro echigadzirwa). Kureba kwegedhi retsono kunofanira kuva 0.8 kusvika 2mm; iyo diki saizi inofanira kusarudzwa kune yakaderera viscosity.

Makomba akajairika ari mukati me 0.05 kudzika, 6 mm yakafara, uye dhizaini angle iri pakati pemakumi matatu.'-1° uye chikamu chegomba chiri pakati pe35'-1°30°.

4. Nyunguduka tembiricha

Inogona kuyerwa ne-in-air jekiseni nzira: kubva pa210℃kusvika ku270℃, zvichienderana neruzivo rwunopihwa nemutengesi.

Buda kuchigaro chekumashure, ita jekiseni rekuumba muchina muromo usiye main chiteshi bushing, wobva waita mawoko kuita jekiseni repurasitiki kuumba, inova jekiseni remhepo.

5. Jekiseni tembiricha

Jekiseni rekukurumidza rinogona kushandiswa, asi kuti udzivise kushushikana kwakanyanya kwemukati, zviri nani kushandisa majekiseni akawanda, akadai seanononoka-anononoka, etc. Kana uchibaya zvikamu zvakakora, shandisa kukurumidza.

6. Nguva yekugara

Kana tembiricha iri 260°C, nguva yekugara haigoni kudarika maminitsi gumi. Kana tembiricha iri 270°C, nguva yekugara haigoni kudarika maminitsi masere.

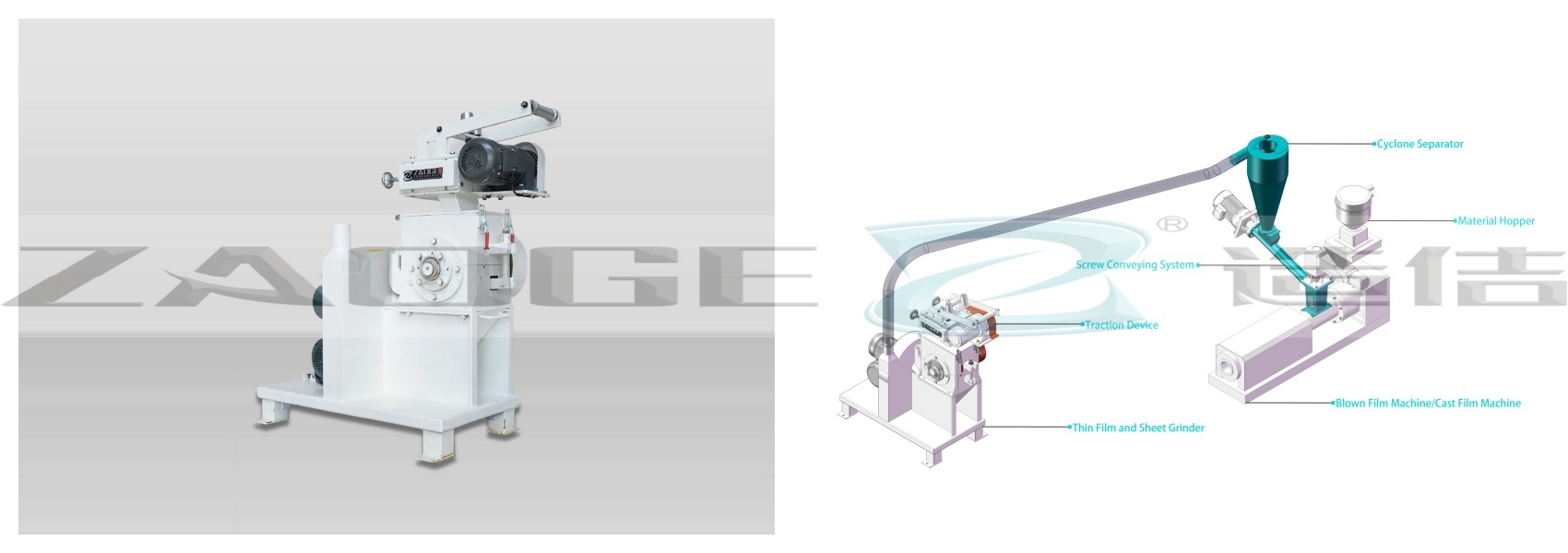

ZAOGE Film Crusherinokodzera kupwanya zvakasiyana-siyana zvakapfava uye zvakaoma kumucheto zvirashwa zvine ukobvu hwe0.02 ~ 5MM, sePP/PE/PVC/PS/GPPS/PMMA mafirimu, mashiti, uye ndiro dzinoshandiswa mukunyora, kurongedza, uye mamwe maindasitiri.

Inogona kushandiswa kuunganidza, kupwanya uye kuendesa zvimedu zvemupendero zvinhu zvinogadzirwa nemaextruder, laminators, mashizha michina, uye maplate michina. Semuyenzaniso, zvinhu zvakapwanyika zvinotakurwa nefin inotakurisa kuburikidza nepombi kuenda kune dutu remhepo inoparadzanisa, yobva yasundirwa muextruder screw feed port neyekudyisa screw yekusanganisa otomatiki nezvinhu zvitsva, nekudaro kuwana kuchengetedzwa kwezvakatipoteredza uye kushandiswa.

Nguva yekutumira: Jul-01-2024